Fiber-reinforced concrete applications and advantages are vast in scope. Surely you’ve heard of concrete being reinforced by materials like rebar, fly-ash, and fibers before, but what’s the purpose of this? Is it something newly developed or has it been around for a long time? Simply put, this process is what strengthens concrete, ensuring the structure’s integrity and security – basically what keeps skyscrapers from toppling over.

Fiber-reinforced concrete applications and advantages are vast in scope. Surely you’ve heard of concrete being reinforced by materials like rebar, fly-ash, and fibers before, but what’s the purpose of this? Is it something newly developed or has it been around for a long time? Simply put, this process is what strengthens concrete, ensuring the structure’s integrity and security – basically what keeps skyscrapers from toppling over.

Fiber-reinforced concrete (FRC) is concrete that has fibrous materials mixed in to increase the concrete’s durability and structural integrity. FRC has small, short, and discreet fibers that are randomly oriented yet uniformly distributed throughout the concrete. Polymeric fibers, generally, make up one to three percent of the concrete mix’s total volume.

So, Why Is Fiber Reinforced Concrete Used?

On its own, concrete lacks tensile strength and is prone to cracking. But fiber-reinforced concrete can improve tensile strength and control cracking in concrete structures that is often caused by plastic shrinkage and drying shrinkage.

Fibers in concrete can also reduce the permeability of concrete, which limits the amount of water that bleeds out, further reducing shrinkage cracking during curing. Our EnviroGuard–100™ is extraordinary at doing this. AtlantisFiber™ has combined years of research by Engineers that specialize in this technology with the removal of tonnes of tire-industry waste to develop two unique admixtures that excel in cracking & shrinkage control and seismic-retrofitting.

Polymeric fibers are resistant to most chemicals and have a high melting point of 165˚C. So it can withstand a working temperature of 100˚C for short periods. Further, since these fibers are hydrophobic, they can also be easily mixed and evenly distributed in the concrete without clumping together.

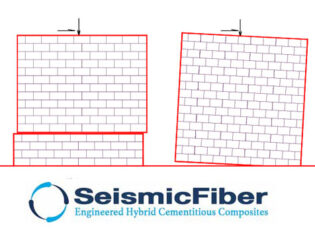

Some polymeric fibers mixes — such as our EDCC SeismicFiber™ blend — are developed specifically to make concrete more impact-resistant and shatter-resistant, showing an incredible residence to high-intensity earthquakes that exceed the 9.0 mark on the Richter-scale. As such our SeismicFiber™ blend reduces the concrete’s need for bulky and cost-heavy steel reinforcements (and less likely to corrode), it makes concrete more cost-effective, saving you time and money on your project or job.

Fiber-reinforced concrete is often used for:

- Ground-level applications, such as sidewalks and building floors

- Basement foundations

- Building pillars

- Support beams

- Bridges

- Burial vaults

- Roadways

- Roof shingles and tiles

- Shotcrete applications—such as pools, basins, agricultural waterways, and rock walls

- Drainage pipes

- Septic tanks

- Sewer systems

- Precast and prefabricated shapes—such as composite decks and thin cement sheets and panels

- Vaults and safes

Mixing Fiber-Reinforced Concrete

Mixing Fiber-Reinforced Concrete

Special considerations such as adding fibers to the concrete before the water is added should be made when mixing fiber-reinforced concrete to help ensure that the fibers are evenly dispersed throughout the concrete mix. This process will ensure you avoid:

- Fibers balling together;

- The segregation of fibers; and,

- A non-uniform distribution of fibers.

In general, fiber-reinforced concrete can improve:

- Workability

- Flexibility

- Tensile strength

- Durability—by controlling and reducing crack widths

- Ductility

- Cohesion

- Freeze-thaw resistance

- Abrasion- and impact-resistance

- Resistance to plastic shrinkage while curing

- Resistance to cracking

- Shrinkage at an early age

- Fire resistance

- Homogeneity

“Results show that in general, there is an increase in compressive strength varying from 1% to 32%, on the addition of fibres to the concrete mix.” ~ Science Direct on Fiber Reinforced Concrete

“It is commonly accepted that FRCs with a low volume fraction of fibres are particularly suitable for structures with a high degree of redundancy where stress redistribution may occur. Because of this redistribution, large fracture areas are involved (with a high number of fibres crossing them) and, therefore, structural behaviour is mainly governed by the mean value of the material properties.” ~ Fausto MINELLI, Giovanni A. PLIZZARI, in Brittle Matrix Composites 9, 2009

In the case of AtlantisFiber™, our SeismicFiber™ blend and our EnviroGuard–100 blend are both designed to not only bring new concrete-mix technology — that serves safety & cost-savings, but also a huge environmental factor — to an enormous industry that is actively taking steps to meet mandates imposed by governments worldwide.