Earthquakes — a force of nature you cannot hide from in almost every place on earth — are most well known around the pacific rim as the “Ring of Fire”. Called the “Circum-Pacific Belt”, this is the zone of earthquakes surrounding the Pacific Ocean, where about 90% of the world’s earthquakes occur. AtlantisFiber™ is headquartered in the Northwestern region of the Ring of Fire, along the Cascadia Subduction Zone (or CSZ).

This Post Concludes Our July Series On Earthquakes

Traditionally, the concrete industry is a very “dirty industry” and the ecological benefit of our discovery and research was to help remove a portion of up to the 300-million metric tonnes of recycled waste from our landfills — and because we tapped into an industry that has a key ingredient readily available, we inexpensively tap into the source and are able to deliver the raw material, passing along the savings.

So How Can AtlantisFiber™ Help?

We developed two solutions by using a mixture of an abundant landfill-destined recycled by-product along with a proprietary blend of other binding elements to create our EnviroGuard–100™and SeismicFiber™admixtures.

Our approach — which incorporates a problematic waste stream from one industry and converts it into a value-added, performance-enhancing additive in another — creates a significant win/win for both industries by simultaneously improving their respective environmental impacts.

Our building solutions are net-zero, cost-effective and have tremendous mixability & compactability. From slab & pre-formed pours to Shotcrete and the need for minimal design impact, AtlantisFiber™ helps you control the traditional concrete process hurdles inherent to working with concrete.

EnviroGuard–100™

Our primary blend, Enviroguard–100™, a Polymeric Fiber Concrete Admixture, is an extracted blend of converted polymer fibers (CPF) sourced from repurposed fiber strands from tires.

Our Synthetic Micro-Fiber blend has been specifically developed to be used globally for a variety of uses in concrete building applications, including parking lots & structures, roadways & infrastructure, commercial on-ground slabs, precast products, pools & pool decks, water retention tanks, and much more where you need your concrete to perform by flexing and not cracking.

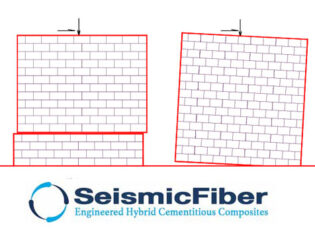

SeismicFiber™ EHCC

Our seismic blend is called SeismicFiber™ EHCC – an Engineered Hybrid Cementitious Composite. Our SeismicFiber™ blend provides a proprietary mixture that excels by being a unique secondary reinforcement that is engineered to be easily workable with seismic retrofit technologies such as Shotcrete. In fact, a 10-millimeter-thick (0.4 inches) layer of our EHCC is enough to reinforce existing interior walls and support structures and is able to withstand seismic events of 9.0 on the Richter scale.

SeismicFiber™ has been developed to specifically be used in applications where structural integrity is crucial, including seismic repair of structures especially those with severe surface defects, seismic retrofitting in schools & buildings, seismic retrofitting on bridges and other infrastructure, shotcrete & seismic spray retrofitting, commercial precast products, blast and impact-resistant structures, 3-D Printing, and likely other application that we have not thought of, yet.