It goes without saying that tires are an amazing invention; the history of how they came about is equally interesting. The original rubber tire was solid rubber, without air, and was used by slow-speed vehicles. Benz invented the first gasoline car in 1888, fitted with metal tires covered with air-filled rubber. This was the beginning of the pneumatic tire, which was first seen by the public in a Paris-Bordeaux-Paris automobile race.

How AtlantisFiber™ Handle Recycling and Helping The Environment

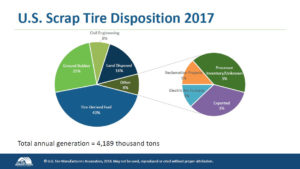

All tires wear out and at least every few years you have to buy a new set of tires. In the United States alone, about 300 million tires wear out every year, however, tires can be reused in many ways.

In the past, old tires usually went to the local landfill or were burnt, and burning old rubber tires releases dangerous toxins and pollutes the air. Additionally, since old tires don’t biodegrade, throwing them away in a landfill simply means they’ll keep stacking up over time, taking up tremendous amounts of space. They also become havens for rats and mosquitoes to breed.

Years ago, some landfills became so-called “tire mountains”-due to the sheer number of old tires that had been discarded in them. In fact, in the 1980s, there were approximately 2-3 billion tires stockpiled in landfills in the US alone. Today, however, as many as 90% of those stockpiled tires have been recycled successfully. In fact, old tires have gone from an environmental nuisance to a recycling success story over the last 25 years. According to the Environmental Protection Agency (EPA), about 80% of (or roughly 240 million) scrap tires now get recycled each year.

In the Beginning: The Birth of the Modern Tire

Circa, 1300s — Word-nerd alert! Historians at the online etymology dictionary write that the in the 1300s, “the notion is of the tire as the dressing of the wheel.” Therefore, “tire” or, if you’re British, “tyre” is simply a shortening of “attire.”

Circa, 1880s — Let’s fast forward some 500 years to 1845. Within weeks of one another, British inventor Thomas Hancock, an American inventor and entrepreneur, Charles Goodyear, were awarded patents for the vulcanization of rubber. Named after the Roman god of fire, vulcanization “is a chemical process for converting natural rubber or related polymers into more durable materials by the addition of sulphur…Vulcanized materials are less sticky and have superior mechanical properties” (Wikipedia).

Soon after Goodyear’s and Hancock’s patents, in 1847, Scottish inventor Robert William Thompson patented a solid pneumatic tire, which uses rubber and enclosed air to reduce vibration. Proving to be too costly, his design never saw production.

Soon after Goodyear’s and Hancock’s patents, in 1847, Scottish inventor Robert William Thompson patented a solid pneumatic tire, which uses rubber and enclosed air to reduce vibration. Proving to be too costly, his design never saw production.

Necessity proved to be the mother of invention in 1888, though, when another Scot, John Boyd Dunlop, developed a tire that would make his child’s tricycle easier to ride over rough Belfast streets. After watching his son suffer from a nasty head cold, he decided to make his child’s doctor-prescribed trike rides more comfortable by attiring his tricycle with tires made of canvas bonded with rubber. As you may have guessed by his surname, Dunlop’s tires were a good deal successful than Thompson’s. Although his subsequent patent was invalidated in 1892 (Thompson had, after all, beat him to the patent office) his invention and his tires quickly caught on, thanks in large part to cyclist Willie Hume’s racing success.

Here’s another name you may recognize: André Michelin. In 1895, he and his brother, Edouard, were first to use pneumatic tires on a horseless carriage. Known to most as the automobile.

Although Goodyear died bankrupt, a company bearing his name, Goodyear Tire and Rubber, was formed in Akron, OH in 1898. The company remains headquartered in Akron to this day.

Circa, 1900s — According to ThoughtCo.:

“In 1903, P.W. Litchfield of the Goodyear Tire Company patented the first tubeless tire, however, it was never commercially exploited until the 1954 Packard. In 1904, mountable rims were introduced that allowed drivers to fix their own flats. In 1908, Frank Seiberling invented grooved tires with improved road traction. In 1910, B.F. Goodrich Company invented longer life tires by adding carbon to the rubber.” And, in 1937, Goodrich developed the first synthetic rubber tire out of a patented substance called “Chemigum.”

At the start of the Baby Boom, in 1946, Michelin developed the radial tire, which far outperformed the bias-ply tire constructed that preceded it. Although the use of radial tire technology spread quickly throughout Europe and Asia (it boasted superior handling and fuel economy numbers), it took a while to catch on in the US. It wasn’t until 1968, when the consumer advocacy publication, Consumer Reports, awarded its two top spots to radial tires. The magazine cited longer life, increased safety, handling, and noted that the in the long run, the costs of running on radials was far less bias-ply tires, which needed to be replaced frequently (Harvard Business School). After a slow start, the radial tire currently enjoys a market share of 100%.

At the start of the Baby Boom, in 1946, Michelin developed the radial tire, which far outperformed the bias-ply tire constructed that preceded it. Although the use of radial tire technology spread quickly throughout Europe and Asia (it boasted superior handling and fuel economy numbers), it took a while to catch on in the US. It wasn’t until 1968, when the consumer advocacy publication, Consumer Reports, awarded its two top spots to radial tires. The magazine cited longer life, increased safety, handling, and noted that the in the long run, the costs of running on radials was far less bias-ply tires, which needed to be replaced frequently (Harvard Business School). After a slow start, the radial tire currently enjoys a market share of 100%.

Run-flat tires are developed in the 1980s to help the driver maintain a constant driving speed and avoid accidents caused by dramatic loss of air pressure.

Circa, 2000s — As of 2007, all vehicles must be equipped with Tire Pressure Monitoring Systems. After the massive Firestone recall in the 1990s, the US Congress mandated the use TPMS on passenger vehicles to help warn drivers of underinflated tires.

The Last Five Years

When you buy a new set of tires today, the dealer will usually recycle your old tires for you. Of course, some people might use their old tires for a new purpose, such as turning them into a tire swing or garden planters. Alternatively, you can check with your local community recycling center for details on how and where to drop off old tires to be recycled.

When old tires get recycled, they’re shipped to a commercial reprocessing plant that uses machinery to break them down into material that can be reused. That material is processed and sorted into tiny pieces with the polymer fiber vacuum-extracted and sorted. Our process is simple, clean, and allows AtlantisFiber™ to be part of the eco-friendly process.

The EPA estimates there are currently more than 110 different products made out of material that comes from recycled tires. For example, recycled tire material is used to make rubberized asphalt, which in turn is used to resurface many roads.

Recycled tire material also finds its way into all sorts of other products, including rubber-encased railroad ties, rubber composite decks, sports courts, running tracks, playground surfaces, public walkways, garden mulch, construction backfill, erosion control barriers, and molded automobile parts, such as engine belts and floor mats.

In some areas, old tires are burnt as an alternative fuel source to generate power. Although old tires can produce as much as 25% more energy than coal, they also produce a lot of emissions and pollutants that are not eco-friendly.

The Future

New technologies are continuing to become commercialized. Pyrolysis, for instance, is the heating of tires in the absence of oxygen to make new materials, such as fuel oil.

There is also a product that has been around for a few years called flexible pavements. With flexible pavements, pieces of tire are combined with rocks or aggregates and a binder like polyurethane to make a flexible, porous surface so that rainwater goes through it and it can bend with movements in the ground—say from tree roots or tree wells.

AtlantisFiber™ has developed Polymeric Scrap Tire Fibers (PSTF), which is an extracted blend of cleaned and refined fibers sourced from the recycled breakdown of tires. This proprietary blend has been specifically developed to be used globally in all types of concrete blends and uses. This technology has shown significant success in mild to extreme climates by forming a self-healing bond with the structure of the concrete, allowing load-bearing sections to possess enhanced structural integrity and reduced cracking by 90%. Read more about that here.