Throughout the process of adding fiber to produce a sustainable concrete mix — like in our SeismicFiber™ blend — AtlantisFiber™concrete mixes can reduce cracks, increase impact resistance, and generally increase concrete strength. It can also take a big chunk out of a long-term problem; concrete’s carbon footprint.

Throughout the process of adding fiber to produce a sustainable concrete mix — like in our SeismicFiber™ blend — AtlantisFiber™concrete mixes can reduce cracks, increase impact resistance, and generally increase concrete strength. It can also take a big chunk out of a long-term problem; concrete’s carbon footprint.

Sustainable Concrete?

Take a bit of this, and mix it with a bit of that, sounds like your typical chemistry class, except that AtlantisFiber™products are more than that just the sum of a few chemicals.

What we have developed is more like enhanced green concrete. Depending on the mixture, a sustainable admixture reduces the carbon footprint enough to call it sustainable concrete… and without sacrificing durability and workability. In fact, our case studies and research shows that not only are our add mixtures good for the environment, they actually increase and improve the performance of the concrete.

“Sustainable concrete is difficult to define. There are many factors that can influence the way concrete is manufactured, designed, built, used and recycled that ultimately affect the environmental footprint of the structures built with concrete.” ~ Specifying Sustainable Concrete by Lionel Lemay, Executive Vice President, Structures and Sustainability, NRMCA; Colin Lobo, Executive Vice President, Engineering, NRMCA; and Karthik Obla, Vice President, Technical Services, NRMCA

It is a well-established fact that the building sector is a major contributor to carbon footprint or CO2eq. In response to the growing concern of climate change, governments are now focused on decreasing the overall carbon footprint by looking at building practices that utilize materials with a smaller carbon footprint. So, since concrete is in over 70% of the world’s structures, we believe that this can be one of the biggest pushes in concrete.

It is a well-established fact that the building sector is a major contributor to carbon footprint or CO2eq. In response to the growing concern of climate change, governments are now focused on decreasing the overall carbon footprint by looking at building practices that utilize materials with a smaller carbon footprint. So, since concrete is in over 70% of the world’s structures, we believe that this can be one of the biggest pushes in concrete.

“The central challenge facing the cement industry reflects that facing all polluters: Cutting emissions without cutting profits. Cement sells so well, after all, because it’s relatively cheap. The sector’s growth also depends on demand from developing countries, where builders can ill-afford more costly materials.” ~ Reuters

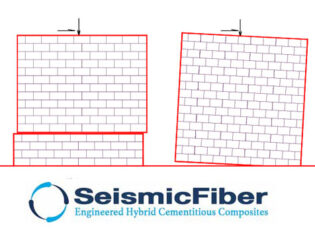

AtlantisFiber’s branded SeismicFiber™, which is made with a specific blend of polymeric fibers and other material, sourced from mostly repurposed material and costs up to 50% less in materials, has faster curing times that speed up construction.

If you are looking to build with concrete or if you have questions, we have answers! Let’s have a chat and we can discover how we can work together on your next sustainable project.