Concrete is the backbone of modern infrastructure and has played a crucial role in the development of our cities and societies. However, sustainability in concrete production practices has a significant impact on the environment, from high carbon emissions to the depletion of natural resources.

In recent years, there has been a growing emphasis on sustainability and reducing the environmental impact of concrete. Creating sustainable concrete is crucial for the construction industry to reduce its carbon footprint and contribute to a more sustainable future. This article will explore the key strategies and best practices for creating sustainable concrete, from choosing environmentally-friendly materials to implementing sustainable design principles.

1. Understanding the Importance of Sustainability in Concrete

1. Understanding the Importance of Sustainability in Concrete

Why Sustainability in Concrete is Crucial for the Concrete Industry

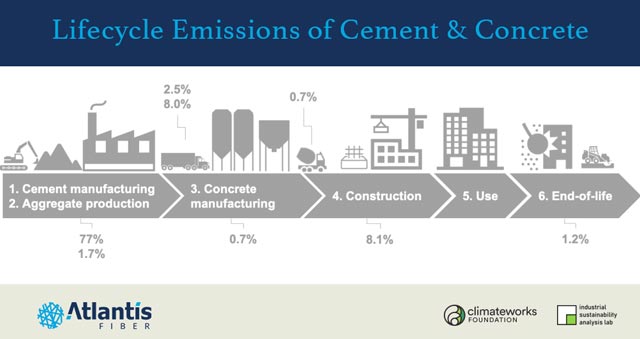

Concrete is the world’s most widely used construction material, but with its high carbon footprint, it has a significant impact on the environment. The production of cement, a primary ingredient in concrete, accounts for approximately 7% of global CO2 emissions. Therefore, adopting sustainable concrete practices is crucial for reducing the environmental impact of the construction industry.

The Benefits of Sustainable Concrete

Sustainable concrete practices not only help protect the environment but also have economic and social benefits. By reducing energy consumption, sourcing materials locally and reducing waste, sustainable concrete can be more cost-effective and increase the durability of buildings. Furthermore, sustainable concrete practices support a healthier environment, mitigate climate change, and improve the quality of life for communities around the world.

2. Implementing Sustainable Concrete Practices in the Construction Industry

Best Practices for Sustainable Concrete Production

Implementing best practices for sustainable concrete production is essential. Concrete producers can reduce the amount of water and cement needed in production, utilize alternative fuels in the manufacturing process, and minimize transportation distances. Additionally, incorporating innovative technologies, such as carbon capture and storage, can capture and store carbon emissions, reducing the industry’s carbon footprint.

Utilizing Local Materials for Sustainable Concrete Construction

Another sustainable practice is utilizing locally sourced materials for concrete production. This reduces transportation distances, results in lower carbon emissions, and supports the local economy. By using locally sourced materials, such as recycled aggregates from construction sites, concrete producers can reduce waste and minimize environmental impact.

Reducing Waste in the Concrete Production Process

Waste reduction is a critical aspect of sustainable concrete production. By reusing, recycling, and recovering waste products from the concrete production process, producers can significantly reduce waste in the construction industry. Sustainable practices include reducing water usage, properly disposing of hazardous waste, and promoting safe work practices.

3. Choosing Environmentally-Friendly Materials for Concrete Production

Alternatives to Traditional Concrete Materials

To reduce the carbon footprint of concrete, producers can use alternative materials such as fly ash, slag cement, and silica fume to replace some of the cement used in production. These materials have a lower CO2 footprint and result in stronger, more durable concrete. Furthermore, incorporating recycled materials like glass and plastic can add another layer of sustainability to concrete production.

The Importance of Sourcing Materials for Sustainability in Concrete

Sourcing materials sustainably is vital for the concrete industry’s sustainability. Concrete producers should work closely with suppliers to ensure that they source materials responsibly and sustainably. This includes using raw materials from low-impact mines, ensuring suppliers follow ethical and sustainable practices, and avoiding materials from high-carbon footprints.

4. Reducing Carbon Footprint with Sustainable Concrete

The Role of Carbon Capture in Sustainable Concrete

Carbon capture and storage is an innovative technology that can help reduce the carbon footprint of concrete production. This technology captures CO2 emissions from the production process, then compresses and stores the carbon underground, reducing its impact on the environment. Incorporating carbon capture into concrete production could reduce the industry’s carbon footprint significantly.

Reducing Energy Consumption in Concrete Production

Reducing energy consumption is another crucial aspect of sustainable concrete production. Adopting energy-efficient technologies such as solar panels, wind turbines, and energy-efficient lighting in production facilities can significantly reduce the industry’s carbon footprint. Additionally, using energy-efficient transportation methods and reducing the distance between the production site and the construction site can help reduce energy consumption in concrete production.

5. Maximizing Durability and Resistance of Sustainable Concrete

5. Maximizing Durability and Resistance of Sustainable Concrete

The Importance of Durability in Sustainable Concrete

Durability is a crucial factor in ensuring the sustainability of concrete structures. A durable concrete structure can withstand harsh weather conditions, resist corrosion, and maintain its structural integrity over a long period of time. This not only saves costs in repairs and replacements but also reduces the environmental impact of construction.

Strategies for Improving the Resistance of Sustainability in Concrete

Several strategies can be employed to improve the resistance of sustainable concrete. One of the most effective methods is the use of high-performance materials such as fly ash, slag, and silica fume. These materials enhance the strength and durability of concrete and reduce carbon emissions. Additionally, proper curing and sealing of concrete can also improve its resistance to harsh weather conditions and environmental factors.

6. Incorporating Sustainable Design in Concrete Structures

Designing for Durability and Longevity

The design of concrete structures plays a large role in their sustainability. By designing for durability and longevity, architects and engineers can ensure that their structures will last for many years with minimal maintenance. This can be achieved by selecting high-quality materials, designing efficient drainage systems, and implementing effective structural solutions.

Using Sustainable Design Principles in Concrete Architecture

Sustainable design principles can also be applied to concrete structures to reduce their environmental impact. For example, incorporating passive ventilation and lighting systems can reduce the energy requirements of a building, while green roofs and walls can reduce urban heat island effects and improve air quality.

7. Innovative Technologies for Sustainable Concrete Production

7. Innovative Technologies for Sustainable Concrete Production

The Future of Sustainable Concrete Production

The demand for sustainable concrete is increasing, and innovative technologies are being developed to meet this demand. New production methods, such as carbon capture and utilization, are being explored to reduce the carbon footprint of concrete production. In addition, the use of recycled materials and advanced manufacturing techniques can further enhance the sustainability of concrete.

New Technologies for Reducing Carbon Footprint

New technologies are also being developed to reduce the carbon footprint of concrete production. For example, the use of bio-based materials as a replacement for cement can significantly reduce carbon emissions. Additionally, carbon sequestration technologies can capture carbon dioxide emissions from the production of cement, reducing the industry’s environmental impact.

8. Collaborating for Concrete Sustainability: Strategies for Stakeholders

The Importance of Collaboration for Sustainability in Concrete

Concrete sustainability requires collaboration among all stakeholders, including designers, engineers, producers, and policymakers. By working together, stakeholders can identify opportunities for sustainability and develop effective solutions that are both efficient and practical.

Best Practices for Stakeholder Collaboration in Sustainable Concrete Production

The best practices for stakeholder collaboration in sustainable concrete production include open communication, identifying common objectives, and leveraging each other’s strengths. By combining the expertise of all stakeholders and fostering a collaborative approach, sustainable solutions can be developed that benefit all parties involved.

In conclusion, creating sustainable concrete is crucial for reducing the environmental impact of the construction industry. From sourcing environmentally-friendly materials to implementing innovative technologies, there are many strategies that can be employed to produce sustainable concrete. By adopting these practices, we can reduce carbon emissions, conserve natural resources, and contribute to a more sustainable future. The journey toward sustainable concrete is ongoing, and it requires a collaborative effort from all stakeholders. By working together, we can create a more sustainable and resilient built environment for generations to come.

FAQ

What is sustainable concrete?

Sustainable concrete is produced using environmentally-friendly materials and methods that minimize its impact on the environment. It involves reducing carbon emissions, conserving natural resources, and improving the durability and longevity of concrete structures.

Why is sustainability in concrete important?

Traditional concrete production practices have a significant impact on the environment, from high carbon emissions to the depletion of natural resources. Sustainable concrete is important because it reduces the carbon footprint of the construction industry and contributes to a more sustainable future.

What are some strategies for creating sustainability in concrete?

There are several strategies for creating sustainable concrete, including using alternative materials such as fly ash or slag, reducing waste in the production process, implementing energy-efficient practices, and using sustainable design principles.

Is sustainable concrete more expensive than traditional concrete?

While the initial cost of sustainable concrete may be slightly higher than traditional concrete, its long-term benefits outweigh the initial cost. Sustainable concrete is more durable, requires less maintenance, and has a longer lifespan, which can lead to cost savings over time. Additionally, the environmental benefits of sustainable concrete can help reduce long-term costs associated with environmental impacts.

1. Understanding the Importance of Sustainability in Concrete

1. Understanding the Importance of Sustainability in Concrete 5. Maximizing Durability and Resistance of Sustainable Concrete

5. Maximizing Durability and Resistance of Sustainable Concrete 7. Innovative Technologies for Sustainable Concrete Production

7. Innovative Technologies for Sustainable Concrete Production