The environmental impact and mechanical behaviour of fibre reinforced concrete (FRC) depends largely on the interactions between the fibres and the brittle concrete matrix: physical and chemical adhesion; friction; and mechanical anchorage induced by complex fibre geometry or by deformations or other treatments on the fibre surface. Surface treatments of the synthetic (mostly polypropylene) fibres have been similarly employed to improve the fibre-matrix bond.

Portions of this blog was originally written in 2018 by Michael Mahoney in “Environmental Impact of Fiber Reinforced Concrete“

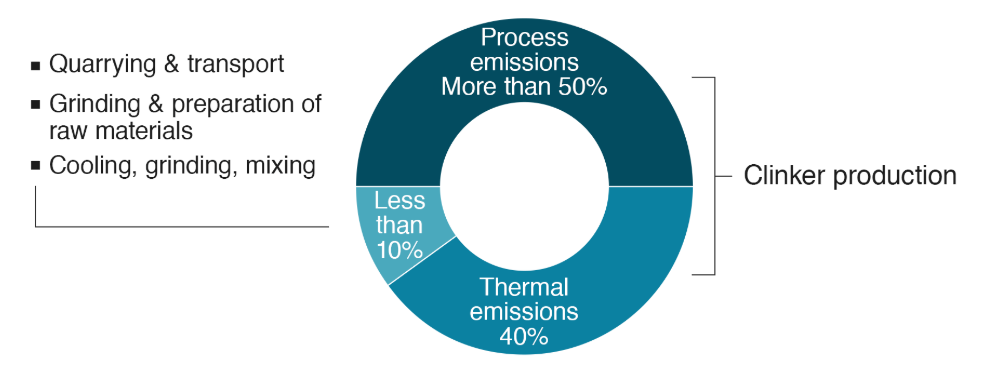

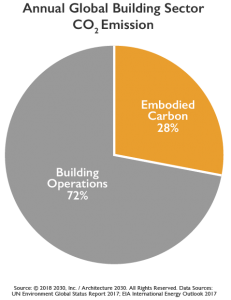

The building sector is a major contributor to carbon footprint or CO2

The building sector is a major contributor to carbon footprint or CO2

In response to the growing concern of climate change, researchers are focused on decreasing Greenhouse Gas (GHG) emissions or carbon footprint by looking at building practices that utilize materials with a smaller carbon footprint.

Polypropylene fiber reinforced concrete (PFRC) is a versatile and high-performance concrete, particularly for industrial and building floors. However, the use of PFRC to reduce CO2eq is not yet well recognized in the construction industry.

A 2013 study undertaken by the University of Akron in Ohio looked at the use of fibre-reinforced concrete as an alternate reinforcing material to conventional steel rebar. The objective of the study was to calculate the CO2eq for the production of a particular macro-synthetic fiber-reinforced concrete floor and compare it to that of a steel-reinforced floor.

“One way to decrease the CO2eq associated with building practices is to use materials that have a smaller carbon footprint. Polypropylene fiber reinforced concrete (PFRC) is a versatile and high performance concrete particularly for industrial and building floors.” ~ International Journal of the Constructed Environment

An extensive literature review was done to develop insight into the methodology that is suitable for the determination of the carbon footprint of the relevant construction materials and processes. Manufacturing processes for both materials, production, transportation and installation into a floor were all provided to a system boundary that included a life cycle analysis up to the completion of construction of the flooring project.

Once the emission factors were compiled, a 150,000 ft2 concrete floor was used as the case study to assess the carbon footprint of the floor using macro-synthetic fibers instead of traditional steel rebar. To ensure a systematic comparison, the concrete mix for both floors was held constant.

Comparing 4.5 lbs/yd3 of macro-synthetic fiber to be functionally equivalent in performance to #4 rebar @ 12” c.c., the carbon footprint of the required PFRC was 20,542 kg CO2eq while that of the steel-reinforced concrete floor was 46,931 kg CO2eq in this case study. This translated to a CO2eq of 0.137 kg/ft2 (8-inch thick floor) with fiber while the corresponding value for steel was 0.312 kg CO2eq/ft2. SOURCE: Environmental Impact of Fiber Reinforced Concrete

Thus, the carbon footprint of a 150,000 ft2 floor could be reduced by 56% relative to the carbon footprint of the corresponding steel reinforced floor.

Large reductions of CO2eq are feasible

Due to the large volume of steel [rebar] reinforced concrete floors used worldwide. The mechanical behaviour of fibre reinforced concrete (FRC) depends largely on the interactions between the fibres and the brittle concrete matrix: physical and chemical adhesion; friction; and mechanical anchorage induced by complex fibre geometry or by deformations or other treatments on the fibre surface.

The “first generation” steel fibres, produced by shearing thin sheets of steel, were not very efficient, because they were too smooth to bond well with the matrix. Subsequently, many different fibre geometries (Fig. 7.1) were developed to improve mechanical anchorage, which is the most important of the bonding mechanisms. Surface treatments of the synthetic (mostly polypropylene) fibres have been similarly employed to improve the fibre-matrix bond. SOURCE: Failure, Distress and Repair of Concrete Structures, 2009

Double-Dipping In Environmental Impact

At approximately 1/5th the energy required to extract and process scrap tire fiber (STF) compared to that of petroleum-based virgin fiber, AlantisFiber’s Polymer Fiber Reinforced Concrete Add Mix widens the gap between the competition even more.

In addition, at AtlantisFiber™, we’re concerned about all our processes through the lens of environmental impact. We source our fiber from a large network of recycling facilities spread across North America making shipping and logistical processes that much more efficient — further reducing our carbon footprint through the reduction of fuel energy and pollution.

A key driver for us is to make the most of the unique advantages that we enjoy based on our extensive network of recycling facilities. “It’s one thing to produce a great, environmentally friendly product and quite another to ensure that all the supporting infrastructure that surrounds it is equally well balanced,” says Pat McConnell, President & CEO at AtlantisFiber™

The building sector is a major contributor to carbon footprint or CO2

The building sector is a major contributor to carbon footprint or CO2